What are DEUTSCH Connectors?

DEUTSCH connectors are industry-leading electrical connectors known for their rugged performance, reliability, and ease of use in harsh environments. They are widely used in automotive, aerospace, marine, heavy equipment, and industrial applications due to their superior resistance to dirt, moisture, salt, and vibration.

Their key features include:

- Sealed Designs: To accommodate a range of applications.

- Multiple Pin Configurations: From 2-pin up to 100+-pin options.

- High-Quality Materials: Thermoplastic housings with silicone seals.

- Secure Contact Retention: Secondary locking systems like wedgelocks ensure terminal security.

Advantages of DEUTSCH Connectors

- Environmental Resistance: Excellent sealing against moisture and contaminants.

- Mechanical Reliability: Designed for secure mating and unmating.

- Serviceability: Field-serviceable with standard hand tools.

- Wide Range of Accessories: Including backshells, strain reliefs, and boots for additional protection.

Tools and Materials Needed

Essential Tools for Assembling:

- DEUTSCH connector tools, including the DEUTSCH crimping tool

- Insertion and extraction tools

- Proper gauge wire

- Contact terminals (pins/sockets)

- Connector housing (plug and receptacle)

- Wedgelock devices

- Optional: Blanking plugs, backshells, boots, strain reliefs

Essential Tools for Disassembling:

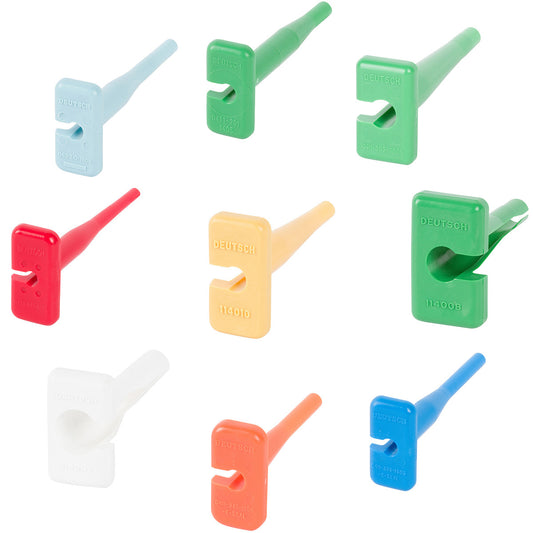

- Extraction tools specific to contact size

- Removal tool for wedgelocks

Assembling DEUTSCH Connectors

Step-by-Step Assembly Guide:

-

Prepare the Wires:

- Strip wire insulation according to terminal specifications (typically 4-6 mm).

-

Crimp the Contacts:

- Insert the stripped wire into the contact and crimp using the designated DEUTSCH crimp tool. Proper crimping contacts DEUTSCH ensures a reliable electrical connection.

-

Insert Contacts into Housing:

- Push contacts into housing cavities until you hear a 'click.' This ensures proper engagement with the DEUTSCH connector housing.

-

Install Wedgelock:

- Snap the wedgelock, if available, into place to ensure proper terminal retention.

-

Consider Upgrades for Longevity:

-

DEUTSCH provides a range of backshells, boots, strain reliefs, and shrink wrap adapters. Adding these upgrades minimizes weak points, prevents gunk buildup, and protects crucial connections for long-term durability.

-

DEUTSCH provides a range of backshells, boots, strain reliefs, and shrink wrap adapters. Adding these upgrades minimizes weak points, prevents gunk buildup, and protects crucial connections for long-term durability.

Disassembling DEUTSCH Connectors

Step-by-Step Guide to Disassembling DEUTSCH Connectors:

Important preliminary steps before beginning disassembly:

- Step 1: Disconnect any Source of Electrical Power: For maximum safely, ensure the circuit that repairs are being done on is not actively receiving power.

- Step 2: Disconnect the Mated Connectors: Disengage locking mechanisms and separate the plug and receptacle housings from each other.

- Step 3: Remove Secondary Lock (Wedgelock): Before extracting any contacts, remove the wedgelock, if present. These devices prevent accidental terminal release. Always use the proper removal tool to avoid damaging the connector housing.

Main Disassembly Steps:

-

Use the Correct Extraction Tool:

- Insert the correct DEUTSCH extraction tool into the inside of the connector depending on the series.

-

Release the Contact:

- Gently depress the locking tab inside the connector, and pull the wire backwards.

-

Remove the Contact:

- Once unseated, the terminal should slide out of the housing easily.

Troubleshooting Tip: Wedgelocks Won't Come Out?

- If you struggle to remove the wedgelock, make sure you are using the correct removal tool.

- Apply sufficient, firm pressure. DEUTSCH wedgelocks are intentionally tight to secure the terminals. Improper tools or insufficient force can make removal difficult.

For more information on troubleshooting DEUTSCH connectors, always refer to the official assembling DEUTSCH connectors guide.

Maintenance and Troubleshooting

Proper DEUTSCH connector maintenance ensures long-term reliability:

- Inspect Regularly: Perform regular DEUTSCH connector inspection to check for dirt, corrosion, and mechanical wear.

- Check Seals: Look for cracks or brittleness and replace if needed.

- Upgrade Connections: Use boots, strain reliefs, or backshells for additional protection, especially in rugged environments.

By following these assembly, disassembly, troubleshooting, and maintenance practices—and considering key upgrades for longevity—you can ensure that your DEUTSCH connectors deliver the rugged performance they are renowned for, even in the toughest applications.